Electrolytic Tin Plate for Recyclability and Cost Benefits in Food

Packaging Containers

Excellent recyclability: a model of environmental protection and

resource recycling

1. 100% recyclable metal properties

Electrolytic tinplate (tinplate) is a metal material with tin on

the surface of a low-carbon steel substrate. It is a completely

recyclable resource. There is no material degradation during the

recycling process and it can be recycled indefinitely

2. Efficient recycling process and low environmental load

No complex sorting is required during recycling. Magnetic

separation can separate metals and other impurities. The energy

consumption is only 1/3-1/4 of the original steel production, which

significantly reduces carbon emissions.

Cost-effectiveness: full cycle advantages from production to

recycling

1. Economic efficiency of materials and production

The thin specifications (0.14-0.5mm) of electrolytic tinplate can

meet the strength requirements of food packaging. The material

consumption is 80% less than that of glass packaging under the same

volume, and the transportation cost is reduced by more than 30%.

The industrial production process is mature, the tin plating layer

is uniform, the welding seal is good, and it is suitable for

large-scale automated canning. The unit production cost is 15%-20%

lower than that of aluminum cans.

2. Hidden cost optimization brought by long shelf life and low loss

The composite structure formed by the tin plating layer and the

steel substrate has excellent corrosion resistance. With the inner

coating, it can effectively block oxygen, moisture and food acid

and alkali corrosion, so that the shelf life of canned food can be

as long as 2-3 years, reducing food waste caused by deterioration.

The packaging container has strong rigidity and better resistance

to extrusion deformation than soft packaging. The breakage rate

during storage and transportation is less than 1%, further reducing

logistics loss costs.

3. Economic closed loop of recycling and reuse

Recycled tinplate can be directly used as a raw material for

steelmaking, replacing part of iron ore. Its market price

fluctuates with the metal market, but its stability is higher than

that of plastic recycled materials.

Dual fit of performance and application: the preferred solution for

food packaging

1,Safety and recyclability are unified: the tin plating layer is

safe and harmless in contact with food, and the recycling process

does not affect the purity of the material, ensuring that the

recycled product can still be used in the field of food packaging.

2,Balance between cost and environmental protection: Compared with

plastic packaging, electrolytic tinplate has significant advantages

in terms of marine debris pollution risk and chemical stability at

high temperatures. The unit packaging cost is only 5%-10% higher,

but the full life cycle cost is lower.

TINPLATE WORKSHOP SHOW

OUR COMPANY

Shanghai Quanjiang Industrial Co.,ltd is a large-scale enterprise

integrating manufacturing and

sales( international export). Established in 2001. With an area of

more than 40 000 square meters.

It's located in Shanghai,China, We has advanced production

equipment, equipped with pushing

machine, press, large heat treatment furnace,chamfering

machine,sawing machine, sawing

machine,large sandblasting machine and other key equipment and a

variety of testing instruments.

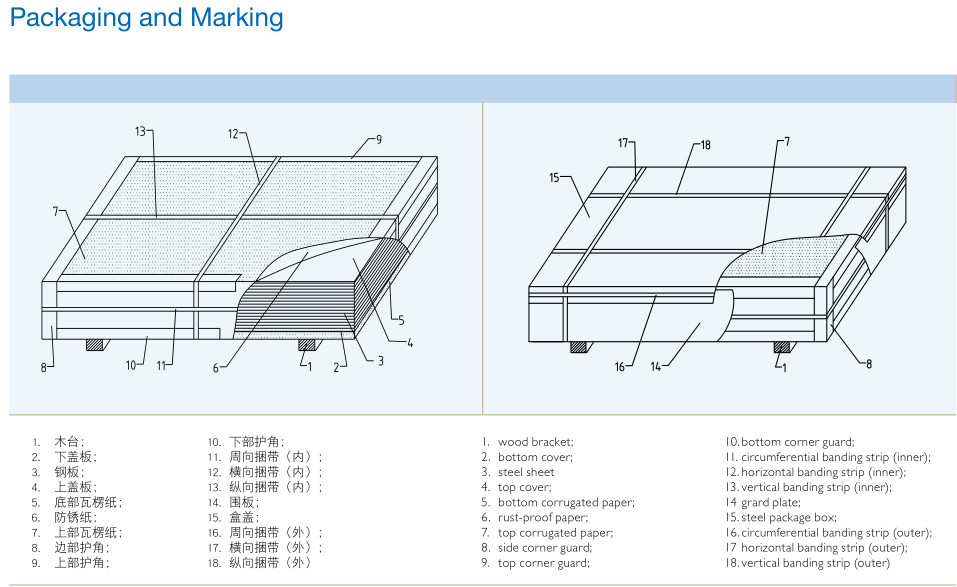

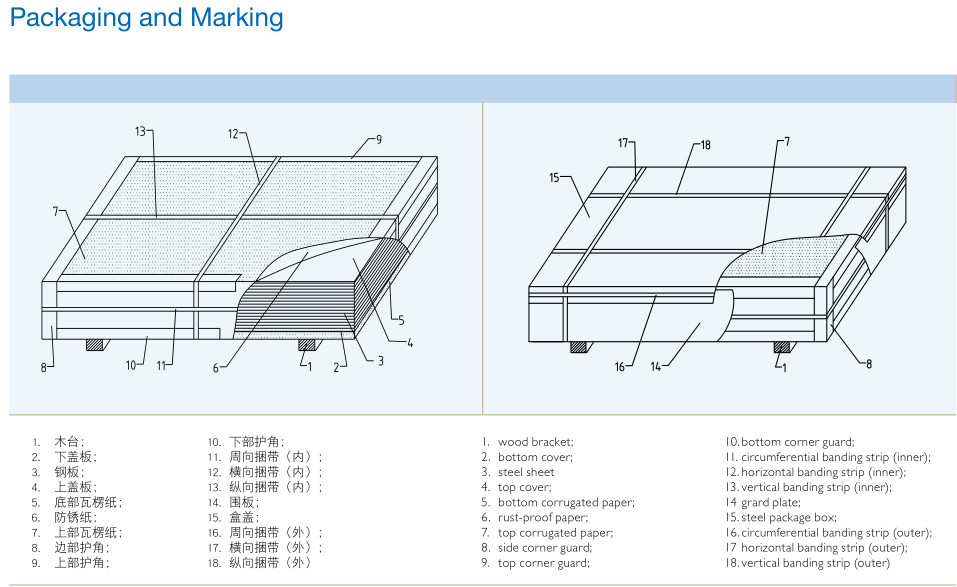

Packing

thin plastic film + rust-proof paper+carton+wooden pallets